where

manufacturing

is a passion

We boast of our manufacturing excellence through our modern and well-integrated plants located in both the northern and southern parts of the country. Our infrastructure is one of the reasons we are a leading mobility solutions provider in India. Initially, as bus body manufacturers, we had nominal infrastructure, but we gradually expanded it into today’s state-of-the-art facilities. Our in-house R&D facilities along with designing, engineering, manufacturing, and testing ensure high product quality at every stage. Spread over a total area of 17,00,000 Sq. Ft ( 1,60,000 Sq. m), our production facilities are well equipped with modern production equipment and adequate technical capacity. To meet the expectations of every customer, JCBL always keeps a constant focus on quality, lead times, and delivery precision while working to ensure health, safety, and well-being for our employees.

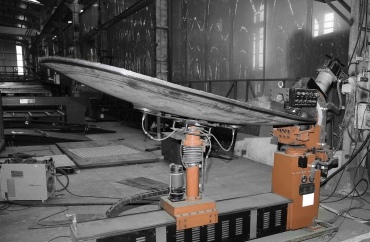

Our facilities ensure a smooth-integrated solution, right from conceptualization to the final fabrication of the product. We use the latest cutting edge technology and machines at every stage of the product evolution - design, construction, manufacturing, and assembly. Quality checks are carried out meticulously to ensure high standards of performance, efficiency, and, above all, safety.

north

JCBL Limited Infrastructure

south

JML Infrastructure

A promise to deliver success with highest precision

Spread over a sprawling area of more than 17,00,000 Sq. Ft ( total area), our state-of-the-art facility has a wide range of general purpose and special purpose machines to facilitate all sorts of manufacturing and fabrication processes. The huge facility is further divided into dedicated areas to enable individual processes involved in the manufacturing of the product. The primary focus of the manufacturing department at JCBL is to ensure that our solutions not only meet specifications, but also pass all quality tests and fulfill all Govt. Regulations, making us the best bus manufacturer in India.

Our Machines and Capabilities

Surface Treatment Processing- Cutting and Bending

Fibre Laser Cutting Machine (4 KW 6020A)

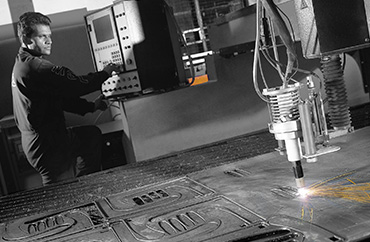

CNC Plasma Cutting Machine

NC Shearing Machine - 1

NC Shearing Machine - 2

5-Axis CNC Machine

Sheet Metal Processing - Bending

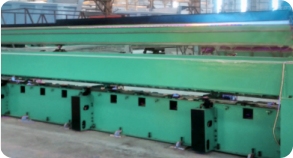

CNC Tandem Brake Press Machine (9 metre)

NC Tandem Brake Press Machine

Panel Rolling

Cargo Panel Rolling

Section Rolling

Sheet Metal Processing

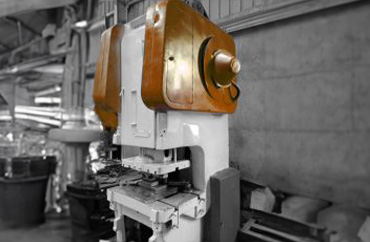

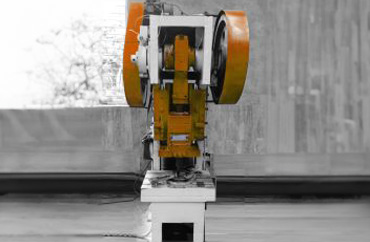

Hydraulic and Mechanical Presses of Different Capacities (10T to 500T)

Welding Process

Laser Welding SPM with IPG Laser (3 KW)

Robotic Spot Welding 4-Axis Machine

Auto Butt Welding Machine

MIG Welding Stations

Gantry Sill I-beam Welding Machine

Machining Process

Double Columns Machining Centre (3*1.5 metre)

Turning Centre

5 - Axis Router

Plano Miller

Surface Treatment Process

Double Door Type Shot Blasting

Paint and Sand Blasting Booth

7 Tank Pre-Treatment

Shot Blasting Booth

Powder Coating

Paint Booth

Pipes and Tubes Processing

NC pipe cutting Machine

NC Pipe Bending Machine

Special Machines for Tanker Manufacturing

Dish End Forming Machine

Dish End Flange Bending Machine

Automatic Butt Welding Machine

Tanker Rolling Machine