POL Tankers

On the highway of growth

Advancing on the highway of growth, we set up the most modern semi-automated petroleum tanker manufacturing plant in Oragadam, Chennai, India in 2018. We are currently manufacturing various types of tankers - Top Loading and Bottom Loading application, conforming to global standards of different capacities. We are known as a leading petroleum tanker manufacturer in India due to high-end tanker manufacturing capabilities.

Types of tankers

- Petroleum Tankers (From 1 KL to 40 KL) [Top Loading and Bottom Loading]

- Water Tankers

- Edible Oil Tankers

- Chemical Tankers

- Fuel Bowsers

- Trailer Tankers

Why choose our Petroleum Tankers?

- Predictable performance on every journey

- Low maintenance & ease of service

- Superior cabin comfort

- In compliance with the industry norms

- Best in durability, reliability and performance

- Effective liquid surge control

- Customized solutions

- Safety fittings certified by PESO

Salient features of JCBL Petroleum Tankers

- ‘Elliptical’ shaped tank- robust and reliable performance.

- Fully Automated Production Line. Delivers much more consistent quality and higher volume production.

- As per OISD 167, API 1004 and PESO recommended practice.

- 4” thick disc partitions. Effective liquid surge control and arrests wobbling.

- Sub Frame Assembly Mounting

- - Reduces the vibration forces and offers smoother rides.

- - Stability Control & Even Load distribution.

- Continuous updating of pilfer-proof design as per OMC.

- ISI marked accessories.

- Unique sump design Ensures the complete draining of the products.

- CCOE approved petroleum road tanker safety fittings.

- Mudguards, Doom Covers, Delivery Valve Box, Shut Off Valve, Lever Box are made out of Stainless Steel (304 Grade) to avoid rust and reduce the maintenance cost.

- Polyurethane Primer and Painting.

- - Hygienic and safe surface finish.

- - High resistance to corrosion.

- - Thermal shock resistance.

- Comprehensive work shop facilities for all type of repairs.

*Actual product specifications and design may vary as per customer requirement

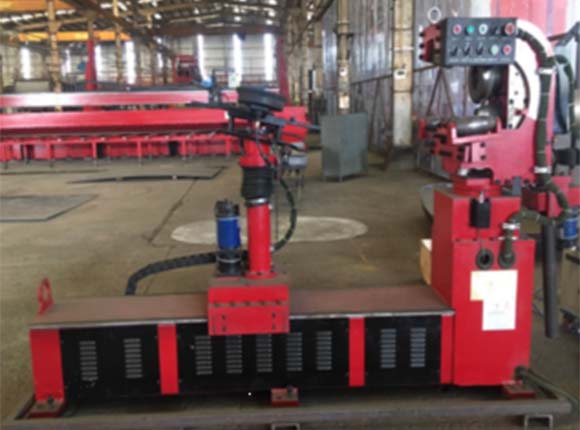

Specialized POL Tanker Machinery

Automated Dish Forming Machinery

Benefits:

- The rubber seal belt is used to pressurize the workpiece. During the procedure, there is no need to change the module. Adjusting the size of the module according to your expected size will be all right.

- The hydraulic system is hanged on the top. The platform on the top has a guiding slot, where the hydraulic pump can move freely to suit different sizes of the workpieces.

- The hydraulic plump has multiple purposes and convenient operation characteristics with powerful pressure and its accessories can also be quite easy to purchase.

Dish Flange Making Machine

Benefits:

- Applicable for different kinds of pressure containers with easy operation, high efficiency and folding quality.

- It improves the collective manufacturing as well as the work environment with highest quality.

- The suitable applications include the automatic fixed distance gland edge folding of regular and irregular tanks, making it particularly suitable for various types of shell tank processing machines.

- The product has won the national patent, and has passed the CE certification.

Fully Automated Butt Welding Machine

Benefits:

- Ensures that the steel is flat, one-side is welded and two sides are well shaped.

- The width of the welding seam is 5-12 mm.

- There are clean and beautiful seam on both sides, round and smooth transfers.

- Ensures eliminating oil, burr, rust and other defects.

Automated Tank Rollers

Benefits:

- It rolls the sheet material according to the shape of the partition bulk head or the dished head. During the rolling process, manual welding in the tank is needed to join the sheet material and the partition bulk head.

- It enhances efficiency while guaranteeing stable quality in the process of mass production.

Automated tank welding for irregular shape tank

Benefits:

- Advanced computer controlling technology.

- Fine appearance of welding seams.

- High welding quality.

- Production efficiency.

- Easy and convenient operation consistently improves both efficiency and quality.

Tank rotators for convenient accessory Fitting & Welding

Benefits:

- Suitable for both types of workpieces, from those with uniform cross-sections to those with variable cross-sections.

- It enhances efficiency while guaranteeing stable quality in the process of mass production.

Safety- Our Utmost Priority

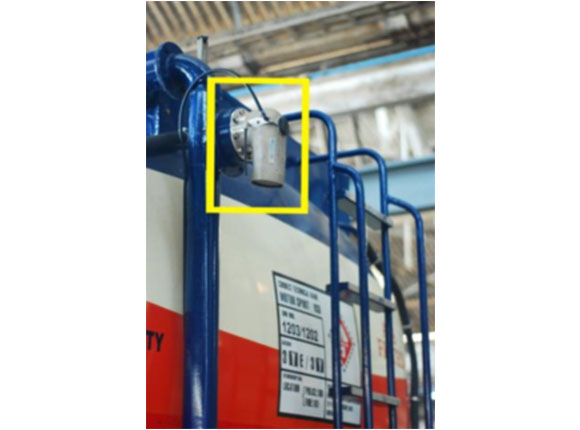

Safety Fittings- Top Loading Petroleum Tanker

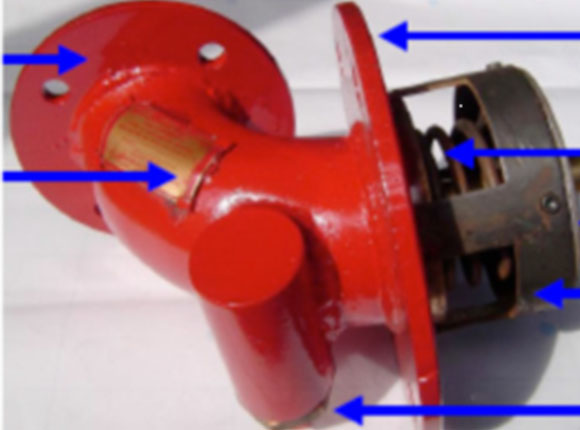

Pressure vacuum valve

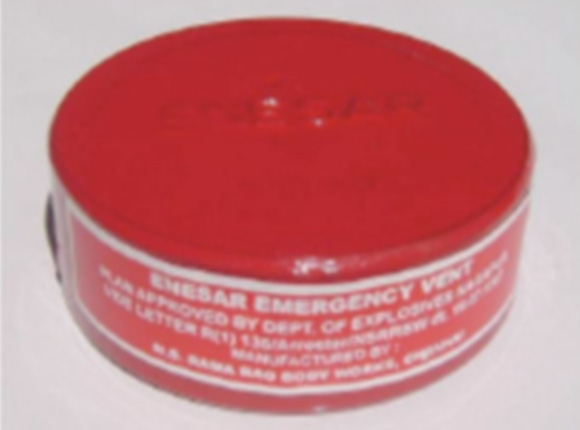

Emergency Vent

Emergency shut off valve

Fusible link

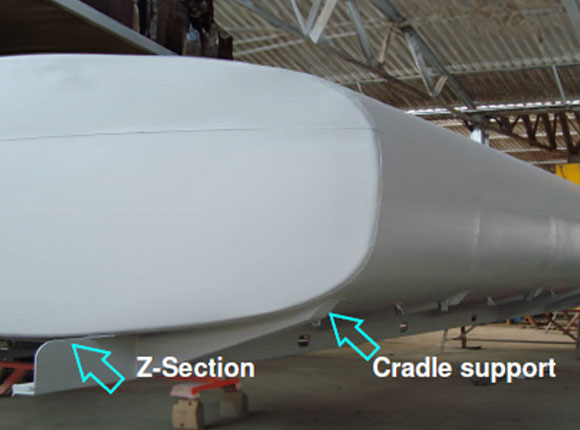

The Z-Section Mounting- Stability Control and Even Load distribution

Manhole Assembly (ALU Construction)

Pneumatically Operated Internal Emergency Valve

( ALU Construction )

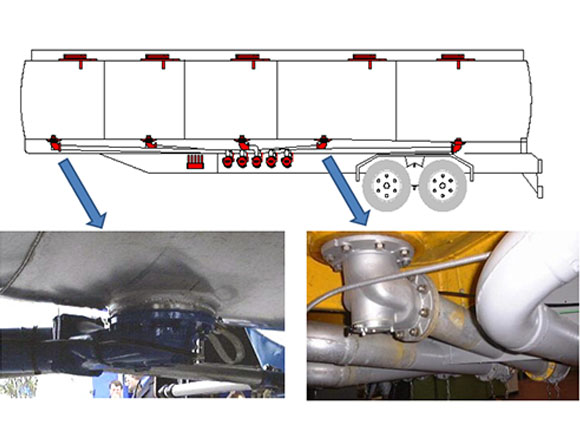

Safety Fittings- Bottom Loading Petroleum Tanker

Bottom Valve Location

Vapour Recovery Adaptor Cap

Vapour Dump Vent (AL Construction)

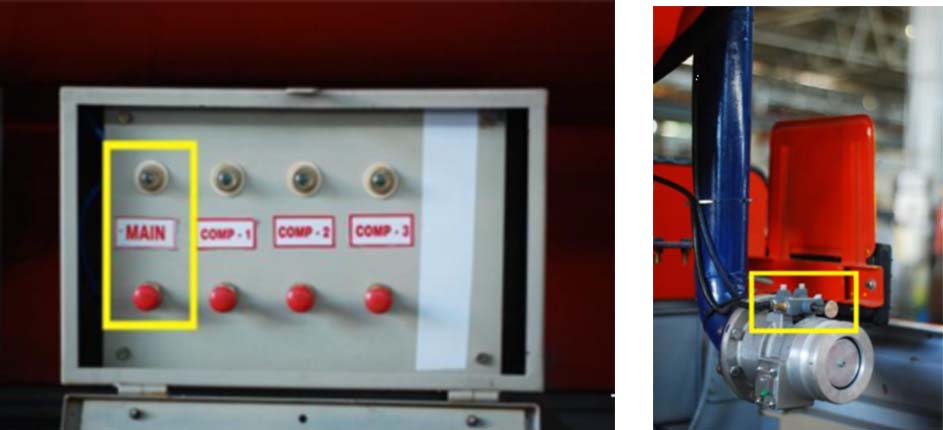

Pneumatic Control Panel

Air interlock valve

Electro pneumatic shutdown push Button

Bottom Loading API Adaptor

API Adaptor Dust Cap

Truck Plug/Socket Two wire /Five wire Optic socket with cap

Battery Cut off switch

Top Loading Petroleum Tanker

Bottom Loading Petroleum Tanker